// From fiber to molded part

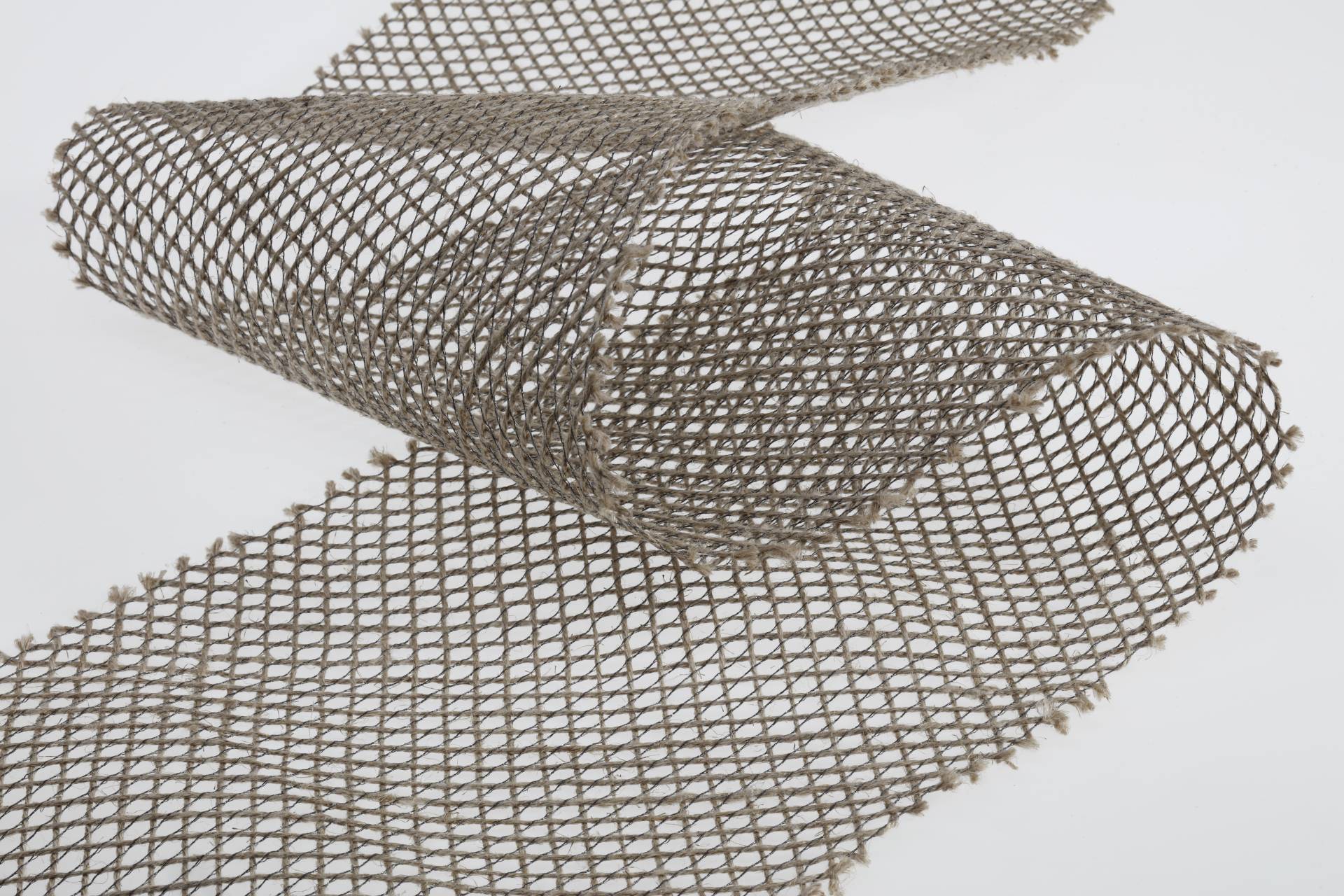

Hybrid textiles from Gerster TechTex enable efficient Production of organo sheetsby combining reinforcing fibers such as glass, carbon, or flax with thermoplastic matrix materials such as PP, PA, or PLA. Processing is carried out using either commingled yarns, fiber yarn blends, or filament yarns, depending on the desired mechanical properties or thermoplastic content. The fiber volume fraction can be customized. The fabrics are bidirectional aligned and can be implemented up to a width of 100 cm. Through the use of Drapfix-bond This results in undulation-free, i.e. non-crimped, fabric structures (non-crimp fabric) with stable edges in both the warp and weft directions.

The textiles are characterized by a high drapability and can be easily adapted to complex component geometries, including concave or convex ones. The freely movable integration of the reinforcing yarns of reinforcement yarns in the knit structure allows excellent post-draping—a decisive advantage during automated forming in heated tool molds. The hybrid structures are ideal for processing in interval presses, enabling fast and economical production of organosheets.

Thanks to their structure, hybrid textiles ensure minimal wrinkling and advance minimizes gaps.. The amount of cutting required in advance is significantly reduced, which lowers overall process costs. This results in a highly functional material systemthat can be processed efficiently and precisely in both forming and consolidation.

// Quick Summary